Commercial Food Processors

Commercial food processors are essential tools in professional kitchens, designed to handle repetitive prep tasks quickly and consistently. Unlike consumer-grade units, commercial food processors are built for high-volume use and can handle dense or delicate ingredients with ease. These machines are commonly used in restaurants, catering operations, institutional kitchens, and bakeries to reduce prep time and improve efficiency.

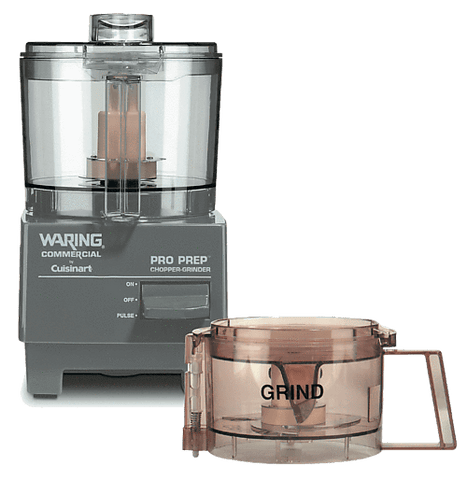

There are several types of commercial food processors, each suited to specific tasks. Batch bowl processors are the most common and come with a bowl where ingredients are added, processed, and then removed. Continuous-feed processors, on the other hand, are ideal for high-volume tasks—they allow ingredients to be fed through a hopper and discharged into a separate container. Combination processors include both a batch bowl and a continuous-feed attachment, offering maximum versatility.

Blades and discs are what make food processors so adaptable. S-blades (or sabatier blades) are standard and used for chopping, pureeing, and emulsifying. Slicing discs allow you to cut ingredients into uniform slices—perfect for cucumbers, tomatoes, and deli meats. Grating and shredding discs are ideal for cheese, carrots, and coleslaw prep. Julienne and French fry blades create stick-shaped cuts, and dicing grids can be used in conjunction with slicing discs to create evenly cubed vegetables.

Food processors can produce a wide variety of textures and cuts that support different culinary applications. For example, using a fine shredding disc, chefs can prepare ingredients for slaws or garnish. A coarse grating disc is better for prepping ingredients like cheddar for melting over nachos or pizza. Puree functions are great for soups, sauces, and dips, while dicing discs can help prepare salsas and salad ingredients. The ability to swap out blades and discs helps kitchens tailor each cut to the dish being prepared.

When selecting a commercial food processor, consider bowl size, motor power, and available accessories. Larger bowl capacities—typically ranging from 2 to 12 quarts—are better suited for operations processing bulk ingredients. Look for models with durable polycarbonate or stainless steel construction and intuitive safety features like locking lids and interlocks. Higher-end models may also offer variable speed controls and programmable functions for more precise processing.

Need assistance choosing the right food processor for your operation? Contact Us toll-free at 1‑855‑380‑6342 or visit our Contact Us page. Our team can help you compare models and attachments to find the best fit for your menu and workflow.